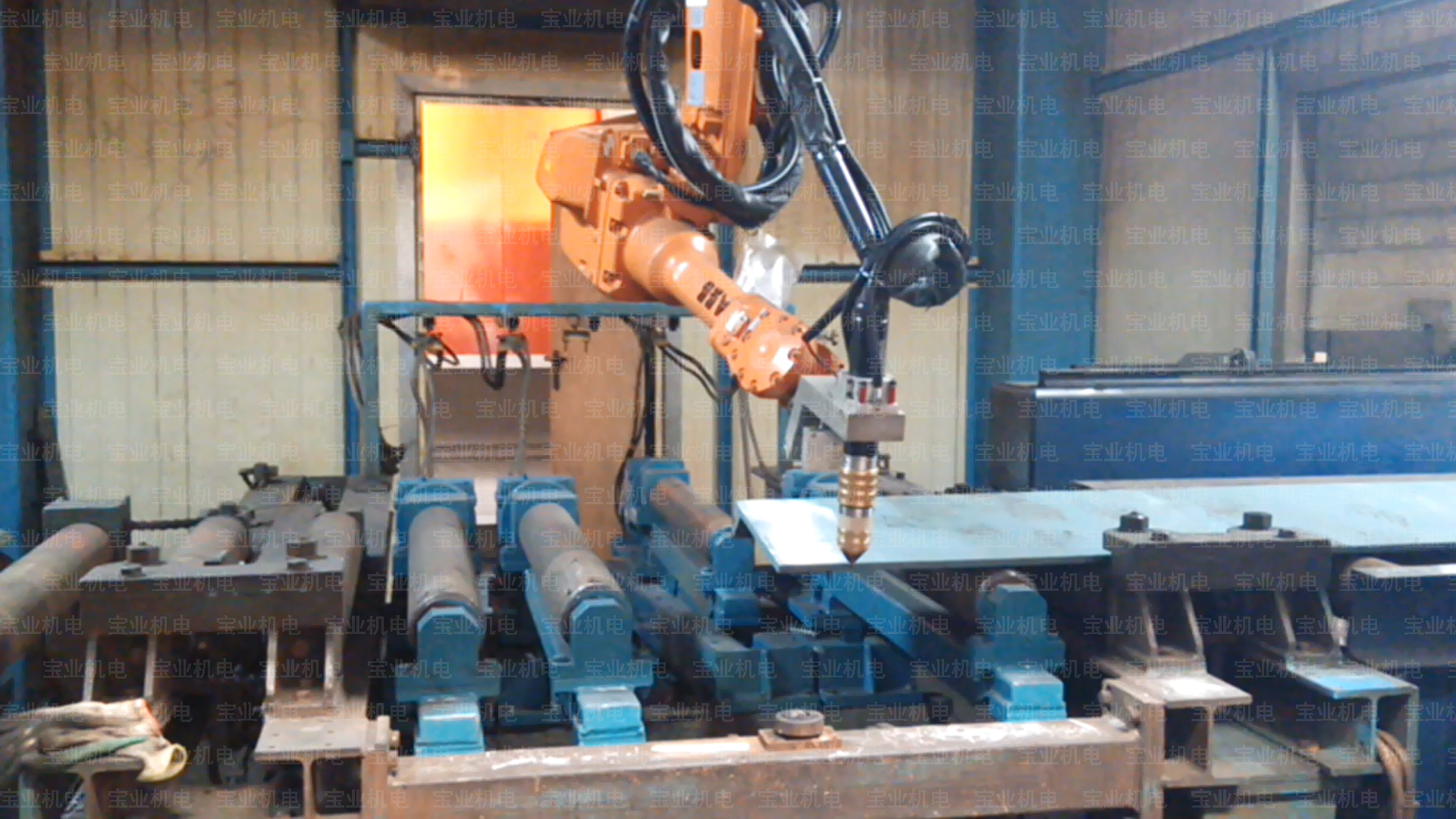

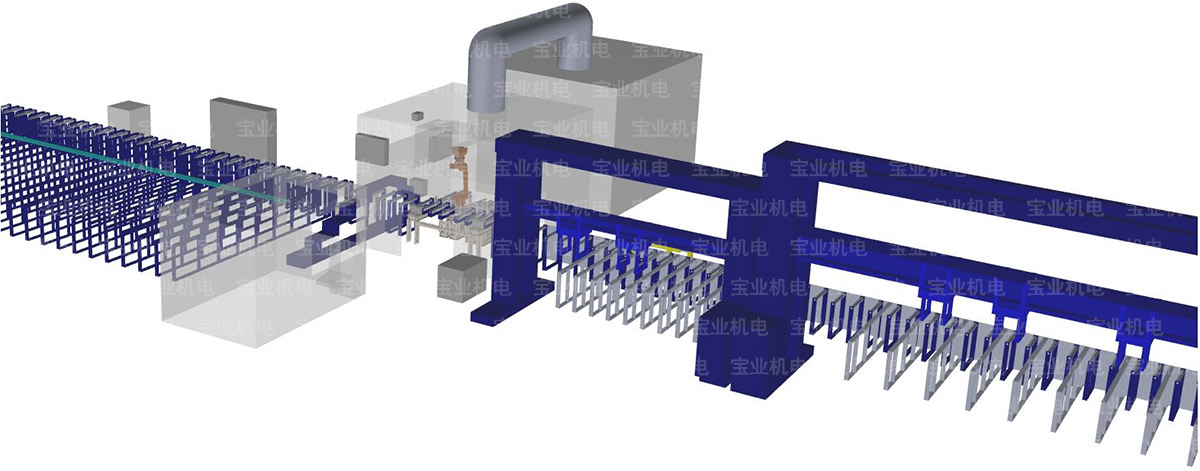

ROBOT AUTOMATIC PROFILE STEEL CUTTING PRODUCTION LINE

●机器人结合专有切割工艺实现多种复杂形状型钢的割断和开孔;

●机器人经过特别防护,可以在密闭空间内抵御粉尘和高温环境;

●结合自动上下料机构,实现全自动无人化生产;

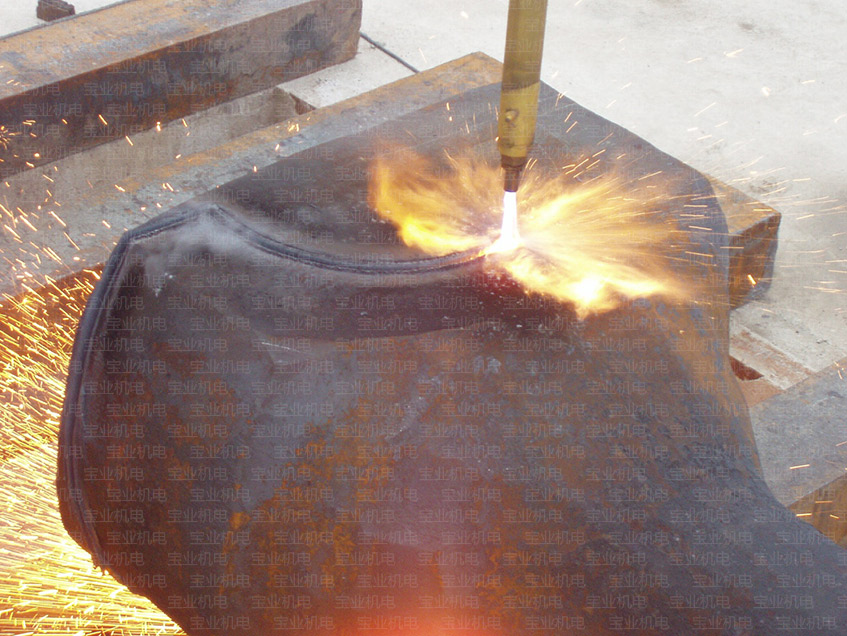

LARGE THICKNESS BILLET CUTTING MACHINE

●超音速高压气割炬能够实现厚达1200mm的钢坯直接进行切割,大幅提升了此类零件的加工效率。

●采用高架悬臂式结构,方便大尺寸工件的吊装作业。

●高可靠性的机械和电气结构能够耐受高热和火焰的飞溅,并保护操作人员的安全舒适。

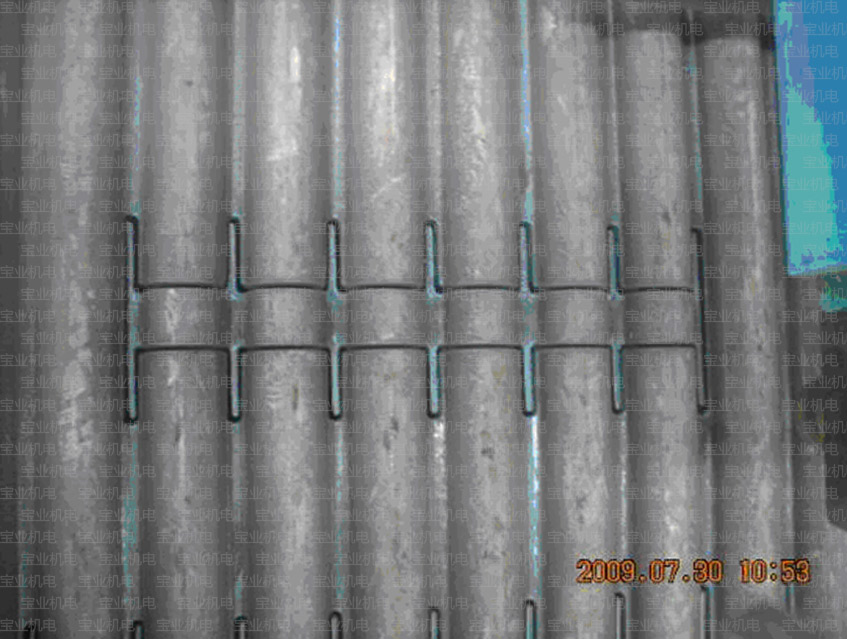

TUBE PANELS CUTTING MACHINE

●割炬结构轻巧灵活、稳固耐用,可以拥有多达六个自由度。

●专有工艺针对难切割部位进行优化,获得令人难以置信的切割效果。

●采用冷加工和热加工相结合的方法,既能保证加工精度,又可以实现较高的加工效率。

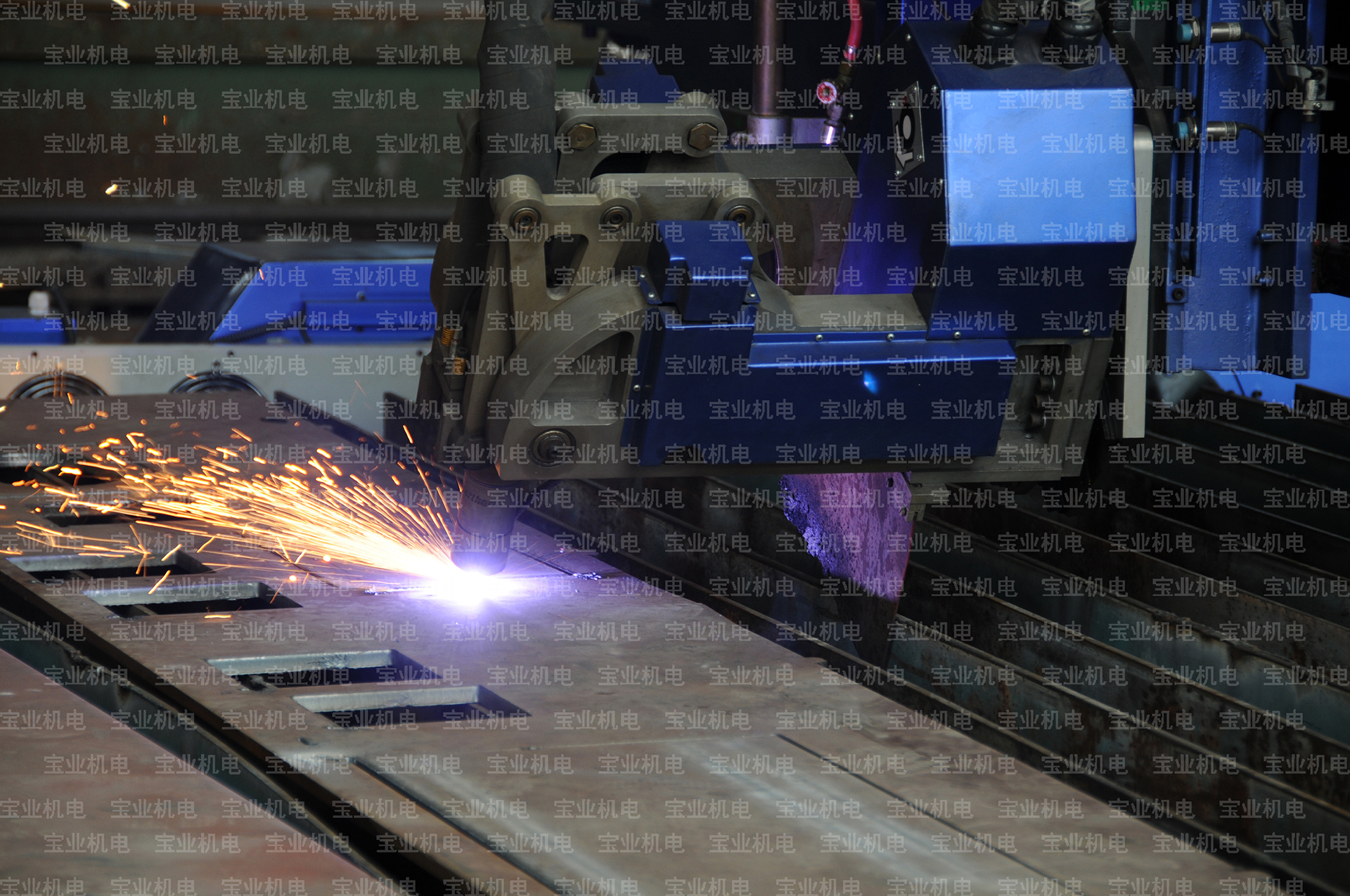

CNC PLASMA AUTO BEVEL CUTTING MATCHINE

BVBA series CNC Plasma Auto Bevel Cutting Machine

BVBA series CNC plasma auto bevel cutting machine is used in the fields of ship building and construction machinery manufacturing etc. The machine is configured with precision plasma cutting torch rotating device and multi-axis CNC system, it can cut the metal plate to parts with variety of complex bevel. Blanking and bevel cutting can be finished together in cutting process. Whole implements greatly savings overall processing time, the cutting quality is also ensured.

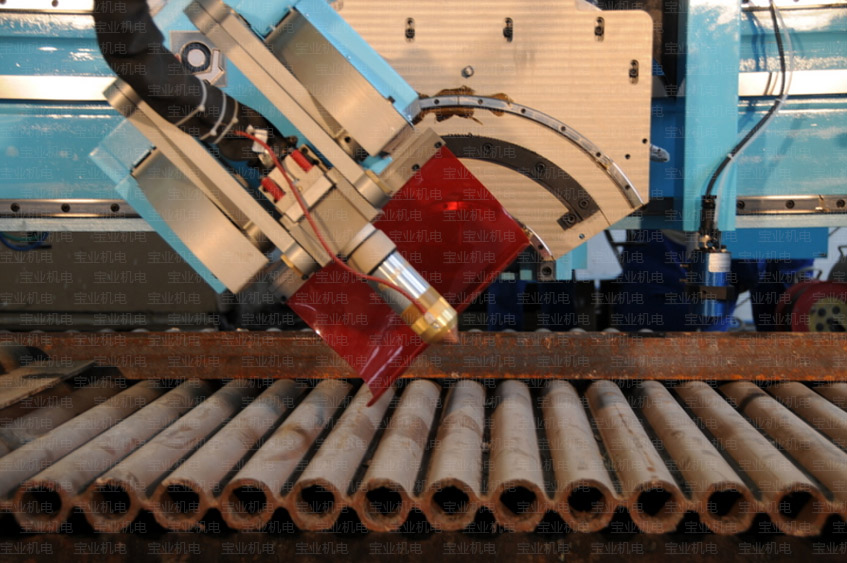

PIPE LINE CUTTING MACHINE

●When cutting, it can adjust the position of cutting torch dynamically according to the sensor, compensate the shape error of the workpiece, and effectively avoid interference in the limit position and workpiece.

●The unique advanced algorithm can realize the precise cutting of complex slope Angle and meet the strict AWS welding standard.