Ship Manufacturing Industry Solutions

Ship Manufacturing Industry Solutions

The company has a variety of special equipment and production line plan for the forming and cutting of plate, pipe and section steel in shipbuilding industry. The production equipment of LNG cryogenic containment system developed by the company has helped Chinese shipping companies successfully break the foreign monopoly and win huge orders.

Auto Climbing Sandblasting Rust Removal System

Set the vacuum recovery device, dust collector, sand blasting and rust removal system.

It is completed from sand blasting, dust removal, pellet recovery, filtration and reuse in a closed system.

It can be used for surface treatment of hull surface welding, sandblasting, cleaning, or removing damaged old coatings.

It can greatly improve work efficiency, ensure cleaning quality and improve workers' working environment.

All wheel differential driving mode, strong load driving ability, flexible steering and steering.

It can climb over the weld seam; the vertical height can be up to 30 meters

Do not destroy the surface of the existing paint in the movement

Specially designed magnetic adsorption system can move freely on the outside surface of ship hull.

Control mode: control mode, wireless remote control is more flexible and remotely operated; Korean system can only operate close to wire.

Load capacity: the load bearing 180kg can drag 30 meters of sand, sand pipe and cable crawling freely in the outer board, free working radius can reach 30m; South Korea system can not bear heavy truck carrying gas sand tube auxiliary coordination, work is inconvenient

Supervision Efficiency: sandblasting width can reach 200mm and work efficiency is higher.

Equipped with video control tracking system, remote control sandblasting effect.

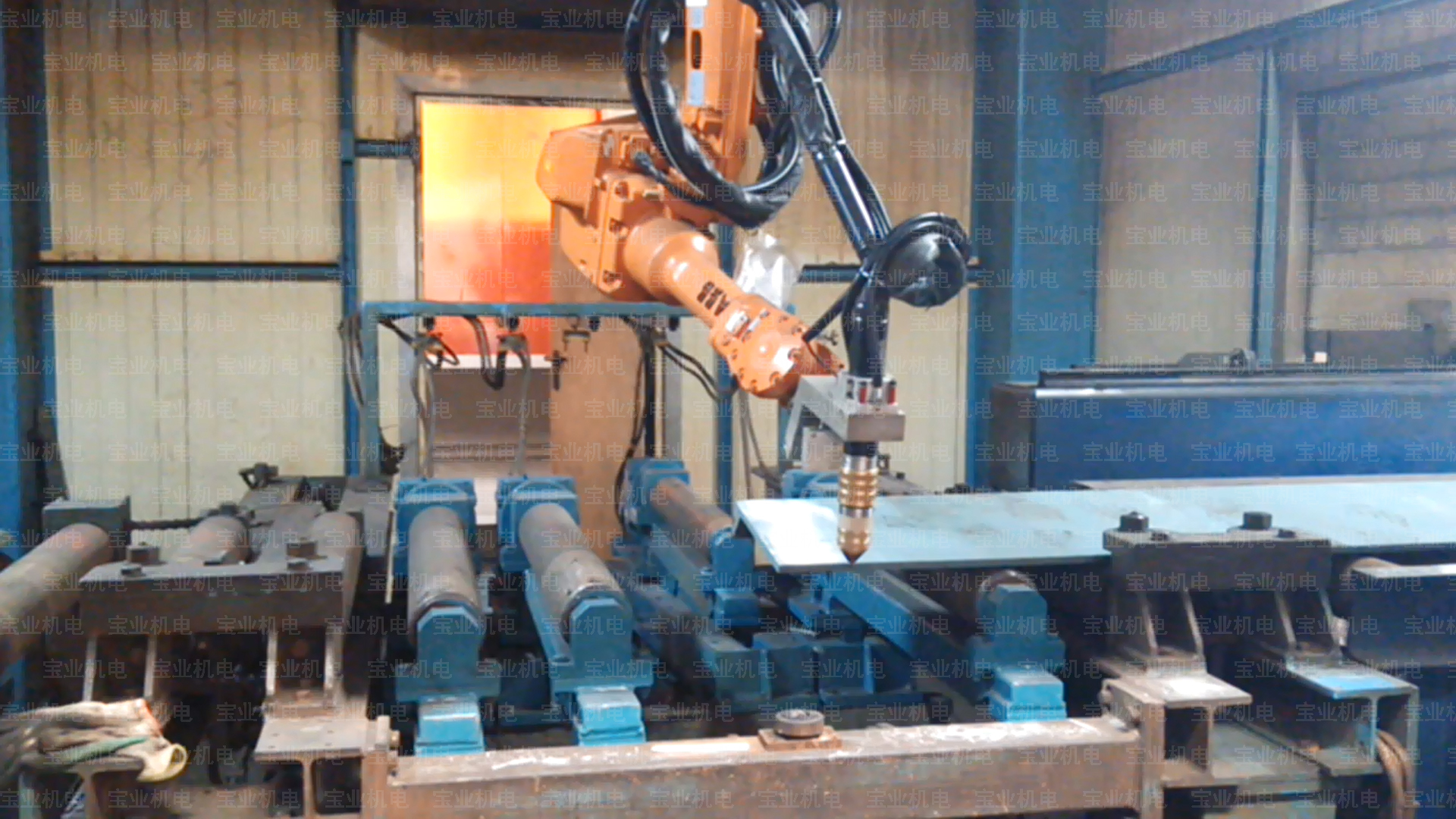

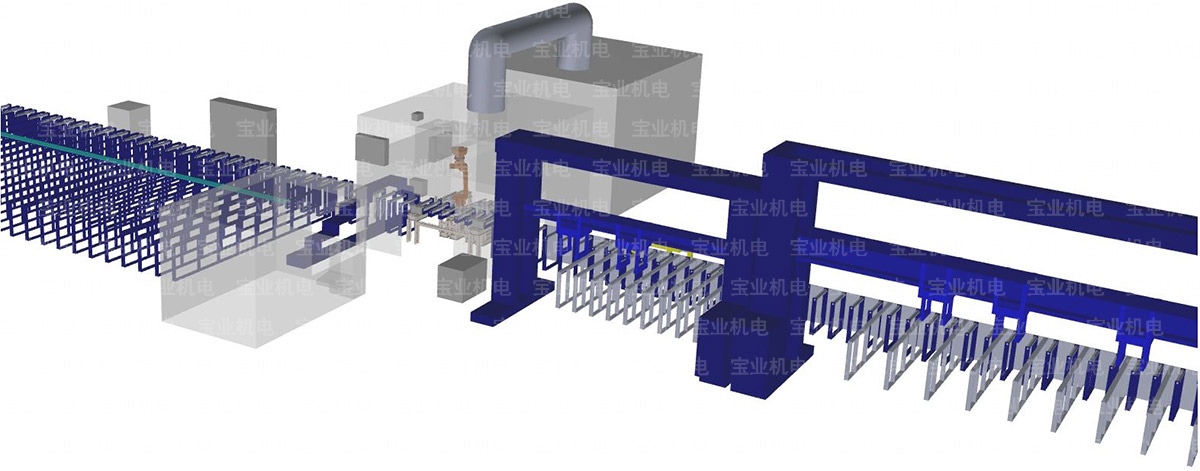

Automatic cutting production line for ship type steel robot

The production line adopts robot trajectory control technology to fuse the mature cutting technology of the company. It can cut the flat steel, angle steel and ball flat steel for high quality cutting in various forms, such as the opening groove and opening of the ball flat steel. And automatic continuous feeding and cutting can be realized to achieve automatic production.

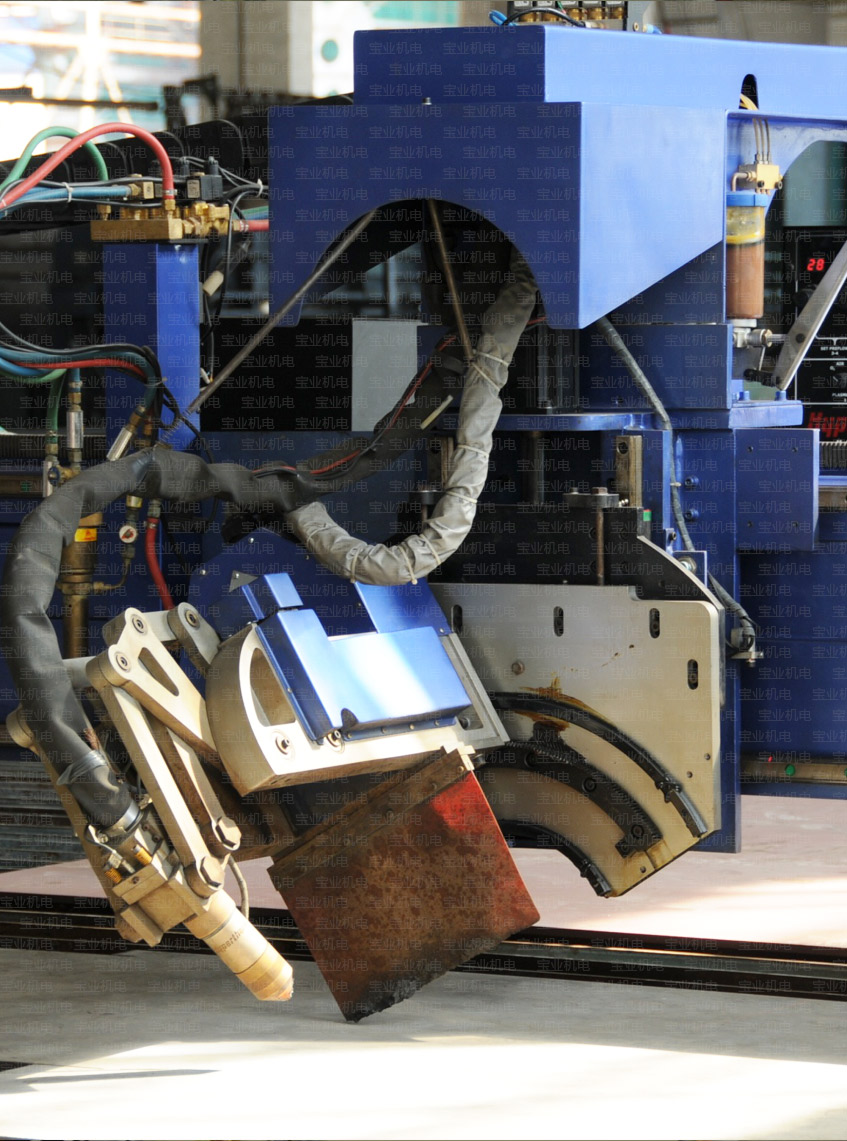

CNC plasma auto bevel cutting machine

The structure of the patent cutting torch is light, flexible, stable and durable, and can have as many as six degrees of freedom. It can realize infinite continuous rotation in the range of 360 degrees. It can meet the cutting demand of complex slope.

The equipment control system has a unique advanced algorithm built in, and is equipped with a graphic programming software that can be quickly mounted. It can cut the complicated angle of various forms and conform to the strict standard of AWS welding.

Typical cutting sample

Main technical parameters:

Maximum positioning speed: 24000mm/min

Slope angle range: + 45 degrees

Angle of rotation: infinite rotation

Plasma cutting torch collision protection device

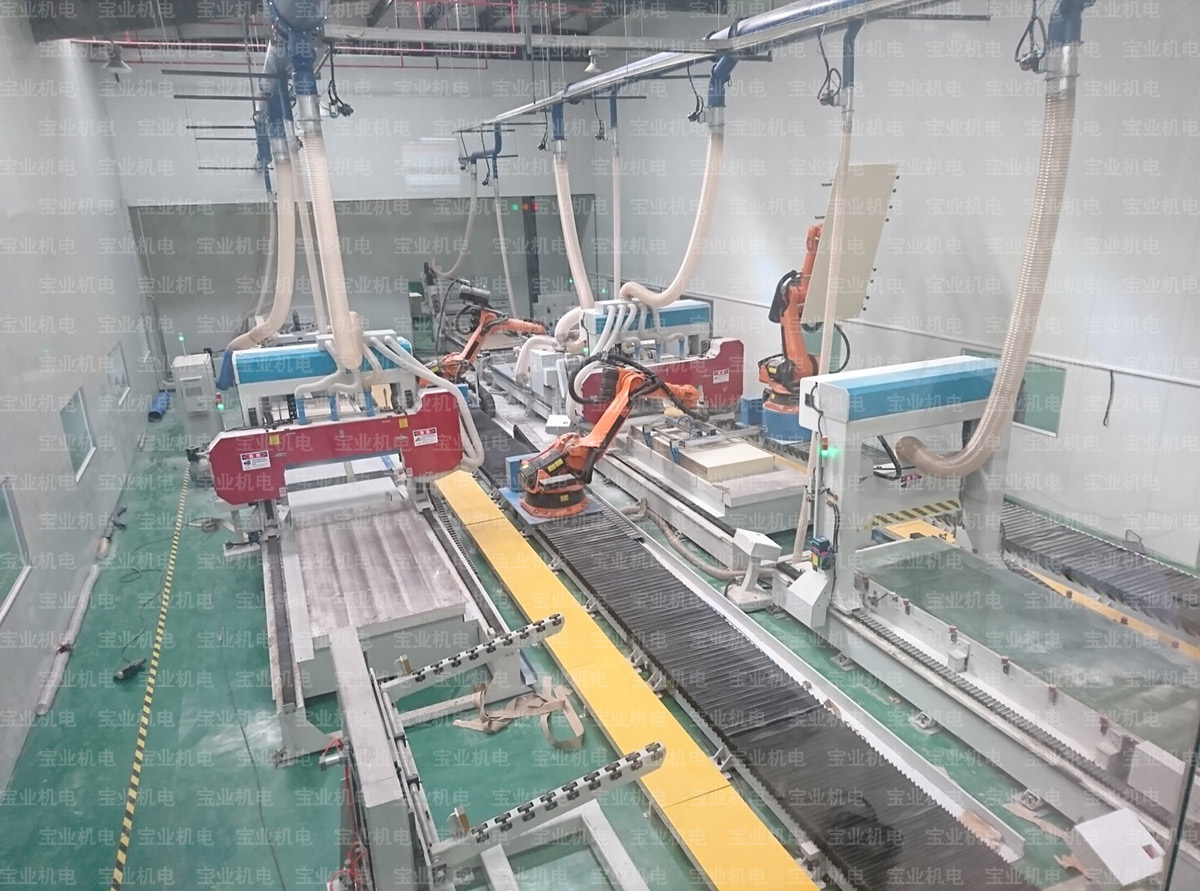

LNG intelligent manufacturing line for marine low temperature enclosure system

Our company has worked closely with the relevant shipping companies to participate in the first LNG LNG carrier development in China. To help domestic shipbuilding enterprises break the monopoly of foreign advanced ships. With the increasing demand for LNG energy in domestic and international markets, we have successfully built and implemented a number of intelligent manufacturing lines for LNG marine low temperature enclosure system, which can be applied to the needs of a variety of LNG ships. The products produced have reached the strictest standards of international classification societies in terms of output and quality.

In view of the low temperature conditions of LNG storage and transportation, most of the materials processed in this production line are new composite materials, which are difficult to process, and the requirements for quality control are very strict. Through the specially developed CNC equipment, the machining accuracy and productivity of such materials are effectively guaranteed.

A large number of robots have been used in the production line instead of manual assembly operations, which reduces the impact of human factors on product quality and enables continuous production of 7*24 hours.

Through strict inspection and quality assurance means, the product line has a high rate of up to 99%, which provides an effective guarantee for improving the precision of the assembly of the whole ship and reducing the loss rate of evaporation.