Metallurgical Industry Solutions

Metallurgical Industry Solutions

As the strategic partner of Shanghai baosteel, the company has been extensively involved in the r&d of intelligent equipment in metallurgical industry. The company's products are used in the key links of steel making, cold rolling, hot rolling, finishing, steel pipe...

Steel Pipe Inspection Control System

The control system of steel pipe flaw detection mainly consists of PLC, touch screen, frequency converter and so on. According to the technology of the flaw detection, the detection speed, the flow of product, the disqualification of the flaw detection and the fault alarm are automatically controlled. The system is mature and easy to operate, and has been successfully applied to eddy current flaw detection and ultrasonic flaw detection of Baosteel precision steel tube Co., Ltd.

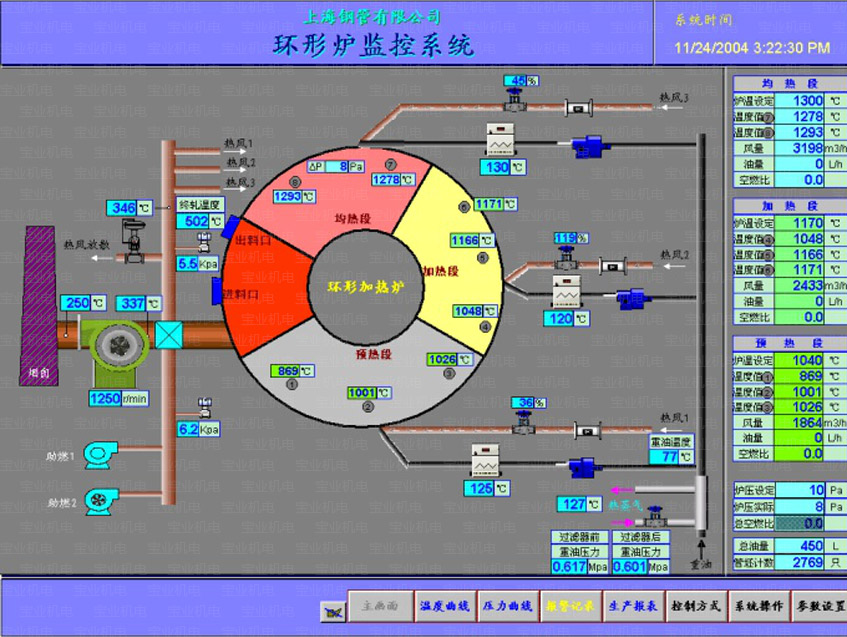

Circular Stove Control System

The EIC three power system is used to supply oil in the way of quantitative pump. The control of heavy oil reheating furnace is realized well. The control system of double cross type is adopted, and the control of temperature, flow rate and air fuel ratio is realized.

DC. Speed Regulator

European SSD expansion product 590P: our company engineer after a long time research, test, developed a new product: high power DC speed control device, the rated working current from 800A to 3000A, since the launch of the market has been widely praised by the majority of users, now widely used in metallurgical, rubber, textile and other industries of direct current transmission system In the system. The device uses Parker SSD 590 primary board and trigger board to control the silicon control module. Through the special integrated structure design, the heat dissipation condition is obviously improved, the work is more stable, and the installation and debugging in the cabinet is convenient. On the basis of all the functions of the original governor, the series governor has a good price performance, and its price is lower than the original 20~50%. It is the first choice for the high power all digital DC speed control system. The DC drive control system of our company has been widely used in metallurgical industry.

Typical applications:

1500A control system of micro stretch reducing mill is applied to many sets of precision steel tubes in Baosteel.

The electric control system 270A*2 of seven roll straightener is applied to many sets of precision steel tubes of Baosteel.

40T-120T drawing machine control system 600-1200A is applied to Baosteel precision steel pipe nearly 20 sets.

The piercing machine control system 1200-3000A is applied to Baosteel precision steel tube and Chang Bao steel pipe sets.

180A of stepping beam DC drive system is applied to many sets of precision steel tubes in Baosteel.

The mandrel DC drive system 180A is applied to many sets of precision steel tubes in Baosteel.

The DC transmission system of steel tube mill is applied to many sets of precision steel tubes of Baosteel.

Fluidized-bed System

This equipment is an experimental equipment and is mainly used for the study of gas reduction of powdery materials (iron ore or laterite powder). The powdered ore material was reduced to fluidized bed gas at 650~950 C temperature, and the sponge iron powder with 50~95% metallization rate was obtained. It will also be used for the selective reduction of low grade laterite to produce low cost Ni Fe alloy. The composition changes of gases and metal containing powdery materials are analyzed. It is one of the important test facilities for the new non blast furnace ironmaking Laboratory of Baosteel Research Institute.

Multifunctional High-temperature Reaction Furnance

The equipment is a laboratory equipment, which is mainly used in different atmospheres to achieve continuous detection of solid state reduction and weight loss in iron ore or carbon containing pellets. According to the conditions of different raw materials, the temperature of the experiment is controlled at 800~1200. Under a certain atmosphere, the melting of materials and separation of slag and iron can be realized, according to the conditions of different raw materials. The experimental temperature is controlled at 1300~1600 degrees C. The equipment has been used in Baosteel Research Institute.

Steel Cans Experiment Product Line

Strip Steel CCD Detection Experiment System

The comprehensive test platform for strip inspection is used to simulate the actual situation of the strip production line, and the CCD detection technology for strip steel is studied in the laboratory. A conveyor platform is set on the test platform. The conveyer table can hold the thin plate with different thickness of 300mmx300mm, smooth and high speed straight line motion, the uniform velocity is more than 300mm, and the uniform speed reaches 200m/min. The light source and camera equipment are arranged around the test platform, the angle of the light source, the distance between the light source and the specimen, the angle of the camera and the distance from the specimen. The equipment has been used in Baosteel Research Institute.

CNC Powder Electrostatic Spraying Equipment

The device uses a numerical control two-dimensional mechanical mobile device to clamp the spray gun or directly install the nozzle on the device. The moving speed, the azimuth and the time can be adjusted and controlled. In the operation, the display can display and track the azimuth of the spray gun (two-dimensional data or figure), and the required film thickness and spraying area are obtained according to the different parameters. . The equipment has been applied to the Institute of welding and surface technology of Baosteel Research Institute.

Automatic Strip Steel Burnishing Equipment

At present, the surface quality of strip steel (especially automobile plate) is getting higher and higher, and the steel plant generally uses CCD to test the surface quality of strip, but it needs to make artificial grinding on the surface of strip before CCD detection, so as to expose the surface defect fully. For this reason, the company specially designed an automatic grinding device, which can be used by the users to grinding both sides of the strip, using two sides elastic to grinding and grinding, using X, Y two coordinate CNC system to drag the grinding head, simulate the hand grinding track and route, and realize the automatic grinding of the strip surface. The device is successfully applied to the 208 unit of Baosteel.

Si-steel Coils Heat Holding Cover

The device is used for thermal insulation of steel coils, so that the temperature of steel coil can be linearly decreased, and the temperature of steel coil can be reduced rapidly in severe cold, and the edge cracks can be reduced, and the yield can be increased. The equipment has been successfully used in Baosteel.

Measuring System of Roller Alignment Use For Straightening Machine

Measuring System of Roller Alignment Use For Straightening Machine

The measuring system of mandrel straightness is mainly composed of guide rail, gear and rack, measuring trolley, sensor support, AC servo motor, laser displacement sensor, integrated controller and industrial computer. It is installed on the hydraulic pressure straightening machine tool body. The laser displacement sensor controls the surface of the mandrel and controls the computer control. The servo motor drive measuring car drives the sensor to do uniform linear motion. The sensor can scan the surface of the mandrel without interruption. After a periodic scan, the offset data of the mandrel surface can be recorded accurately. The maximum bending point and offset of the mandrel can be calculated by processing. It can be connected with the straightener in the production process, and effectively improve the production efficiency and product quality. It provides an effective, objective and high precision measurement standard for measuring the straightness of the mandrel. Straightness measurement accuracy: less than 0.5mm/m (full length less than 2mm) (without considering the deformation of press bed). The device has been successfully applied to Baosteel Changzhou rolling Co., Ltd.

Numerical control steel coil end heating equipment

In order to prevent the cold rolled steel roll (especially the silicon steel roll) in the opening and cutting edge crack and influence the quality of the product, the cold rolling finishing line needs to heat the edge of the steel coil to ensure that the side of the coil can reach a certain temperature when the roll is open and cut. The equipment uses a self-designed manipulator with controllable speed and trajectory to drive two heating plates (each heating disk installed 6 burner) to heat the two ends of the steel coil, and automatically adjusts the heating temperature by measuring the size of the flame, the time of heating, the track and the temperature of the side of the steel coil to satisfy the opening of the coil. The need. Generally, the heating temperature can reach 80-100 degrees within the wide edge of 60mm. The equipment has been put into operation in Baosteel's 1580 production line.

Main technical features: the use of advanced numerical control technology, servo motor drive, automatic control of the gas heating disk running track and running speed, to ensure that the flame is effective and uniform coverage of different diameter steel coil end. Automatic control of target temperature and automatic adjustment of air-fuel ratio.

Suitable for steel: oriented silicon steel and non oriented silicon steel.

Coil Sample Cutting Equipments

The function of the coil sampling unit (including flame or plasma cutting system) is to sample the hot-rolled coil head of the hot rolling mill which is more than 6.0mm thick. The steel coil is mainly made of thick plate high tensile steel (tensile strength up to 1000Mpa), high strength weathering steel, automobile steel and so on. Sampling process combined with robot can achieve complete automation. The unit has been successfully applied to Baosteel and Lian steel.

Roller Clean Equipment

The device is mainly composed of wiping head, pressure mechanism, horizontal horizontal moving mechanism, dust collecting and collecting mechanism, dust removal line, dust removal unit and electric control system. It is mainly used in the hot rolling finish leveling unit. The upper and lower supporting rollers of the unit are equipped with roll wiping device, which can be used to remove iron oxide chips on the surface of the supporting roller and keep the roll surface clean. The device is installed on the archway at the exit of the leveling machine, and the wiping head is pressed on the supporting roller surface through the hydraulic cylinder, and the synchronous gear wheel is driven by the motor, and the ball screw nut mechanism can be moved horizontally in order to wipe the length of the whole roll. Wipe the wiper strip with two cylinders to wipe the oxide powder and oxide scale on the backup roll. Through the manual adjustment of two upper and lower hand wheels, the tension and the replacement of the wipes are carried out. The ball screw nut mechanism is equipped with a telescopic protective cover. A dust removal system is used to collect iron oxide chips. The equipment has been successfully applied to major steel mills in Baosteel, Shougang, Chongqing Iron and steel and Benxi steel.