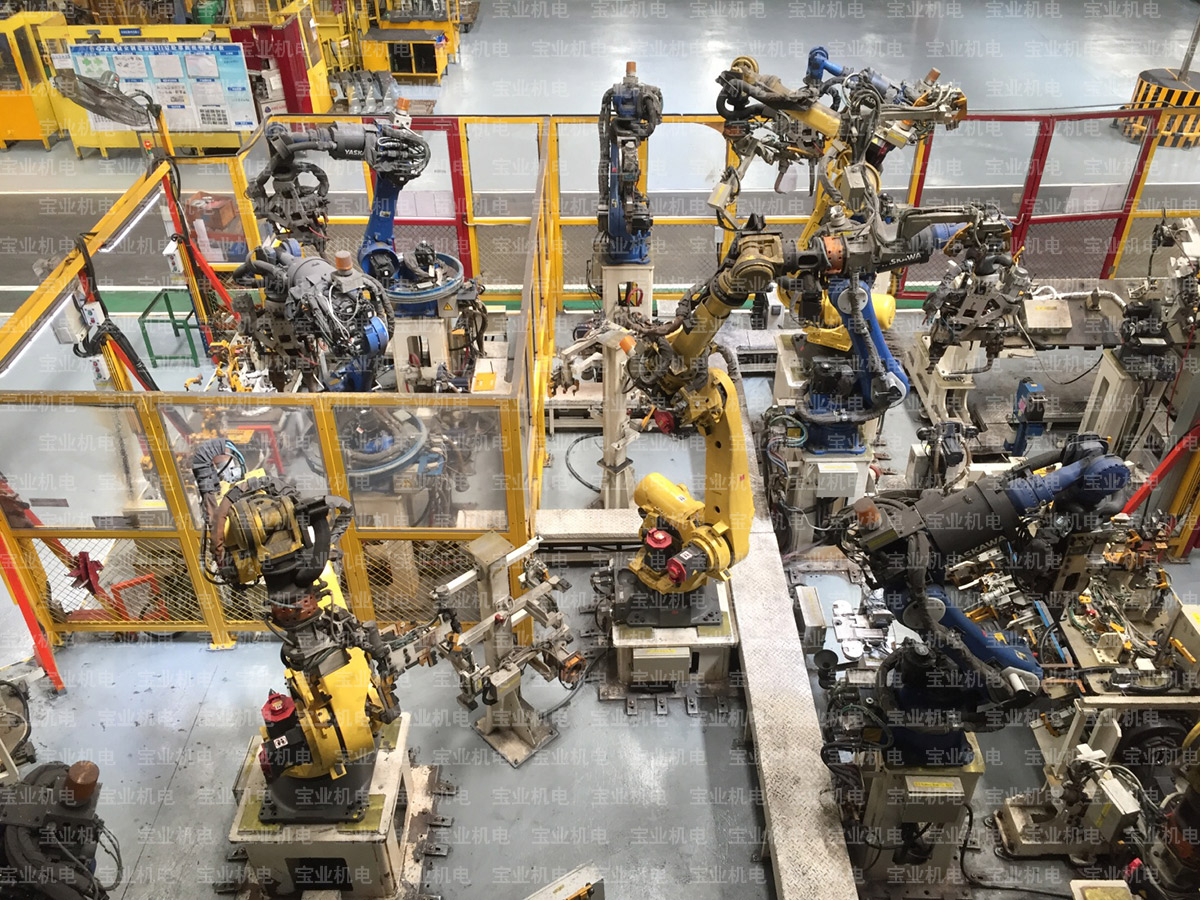

The fixture warehouse can store 3 models and a total of more than 70 sets of fixtures. It can meet the needs of more than 20 robot welding workstations.

In some processes, multiple robots need to cooperate with each other to complete a task together. Shanghai Bao Industry combined with many years of experience in robot applications, the use of multi brand of robots on the production line, and let different brands of robots play their own strengths and work together.

The intelligent fault proofing design is adopted in the production line, which effectively avoids human errors in the feeding section and affects the normal flow line of the production line.

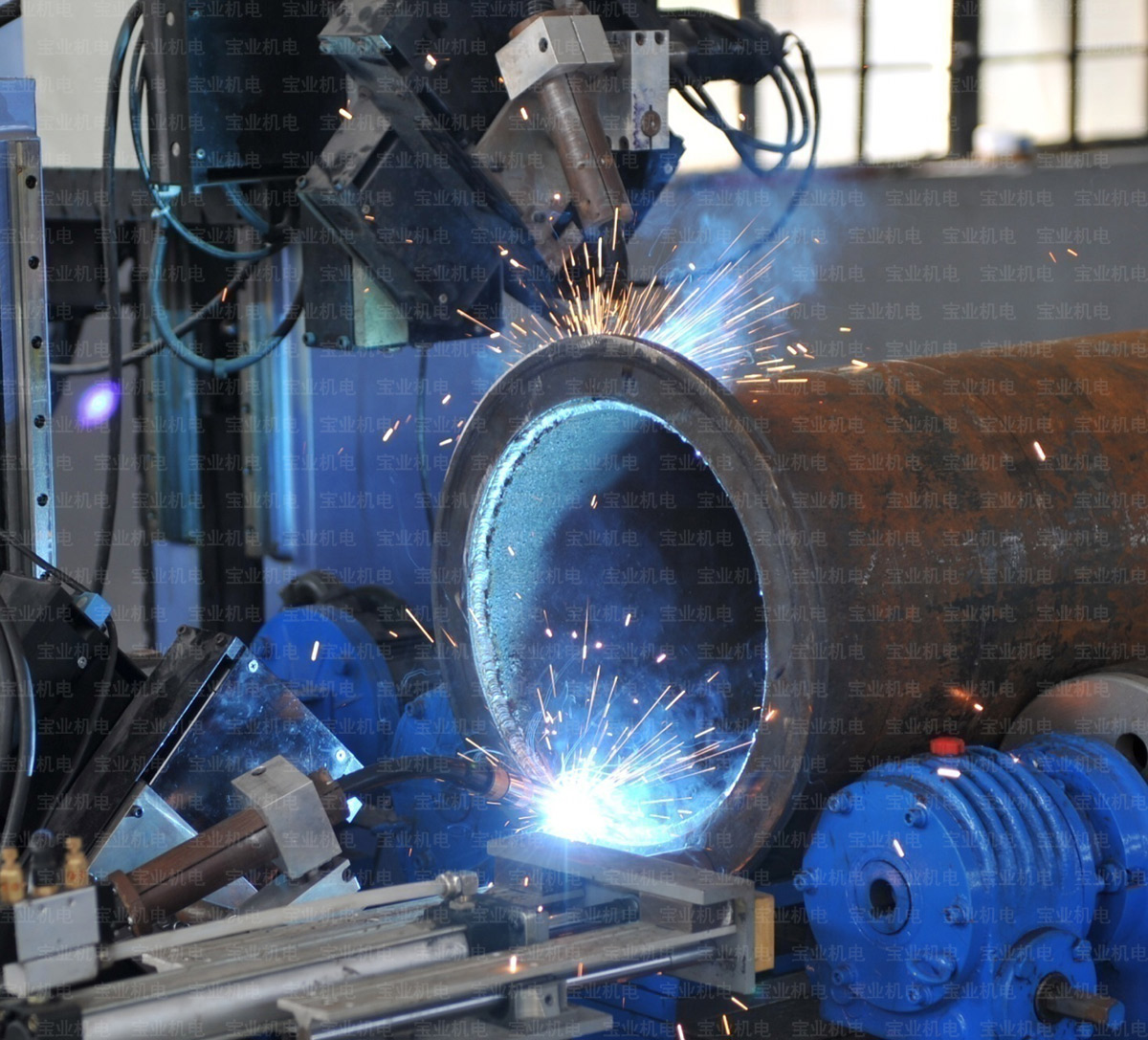

The equipment is suitable for ships, petrochemical industry, electric power tower and other industries. It is not only suitable for inserting flanges in the form of welding, but also for the welding of butt flange assembly. The ideal weld forming greatly reduces the grinding time and the waste of welding materials.

The welding gun position can be adjusted at any time according to the irregular gap between pipe, straight pipe and flange, and the distance between the end face of the pipe and flange, such as swing, so as to ensure the welding quality and the appearance of the weld.

The automatic welding control system is composed of the programmable controller as the core of the flange welder. The control cabinet has an operating panel and a human-computer interface, which is intuitively and conveniently operated. The welding power source uses the international leading level welding power source, the performance is stable and reliable.

During welding, the welding torch can oscillate according to the setting mode, and can form high quality welds and reduce the problems of sticking guns.

© Copyright SHANGHAI BAOYE M&E TECHNICAL CO.,LTD All rights reserved