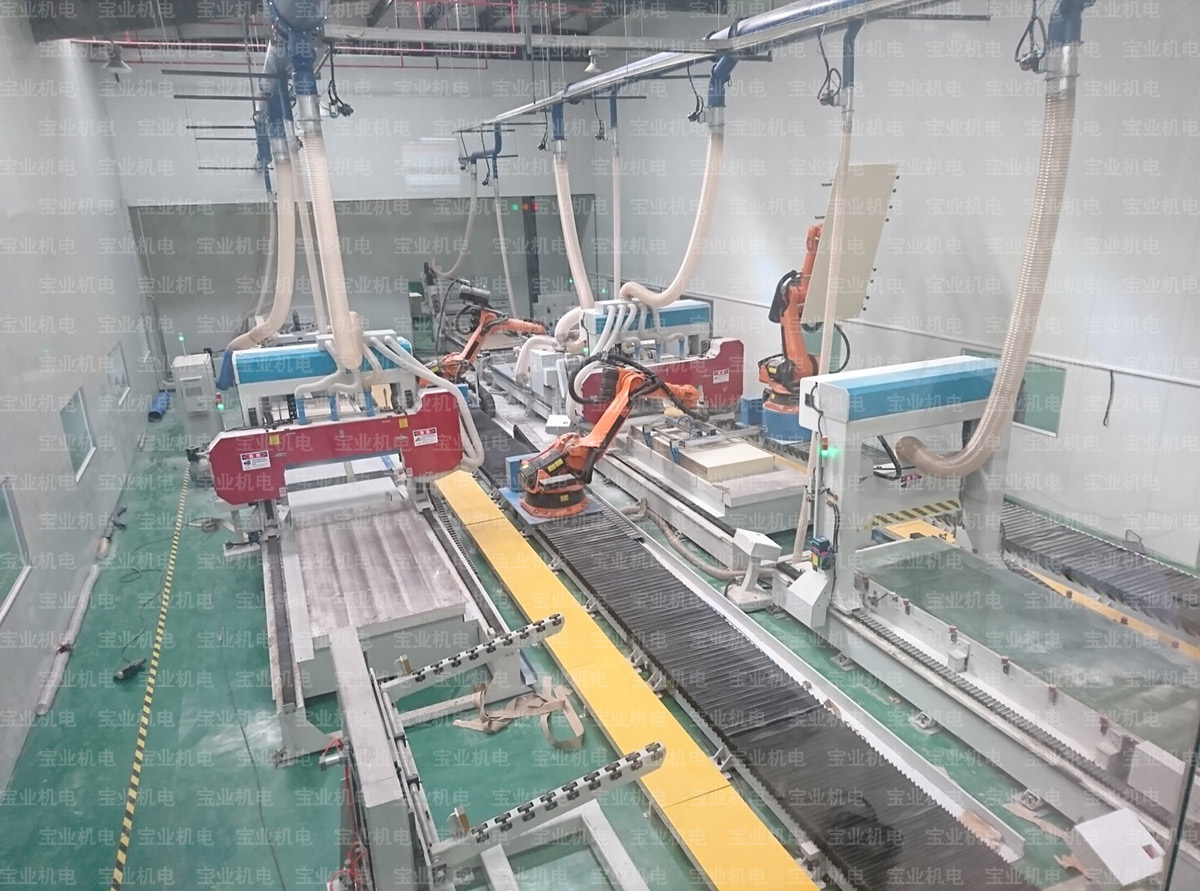

In view of the low temperature conditions of LNG storage and transportation, most of the materials processed in this production line are new composite materials, which are difficult to process, and the requirements for quality control are very strict. Through the specially developed CNC equipment, the machining accuracy and productivity of such materials are effectively guaranteed.

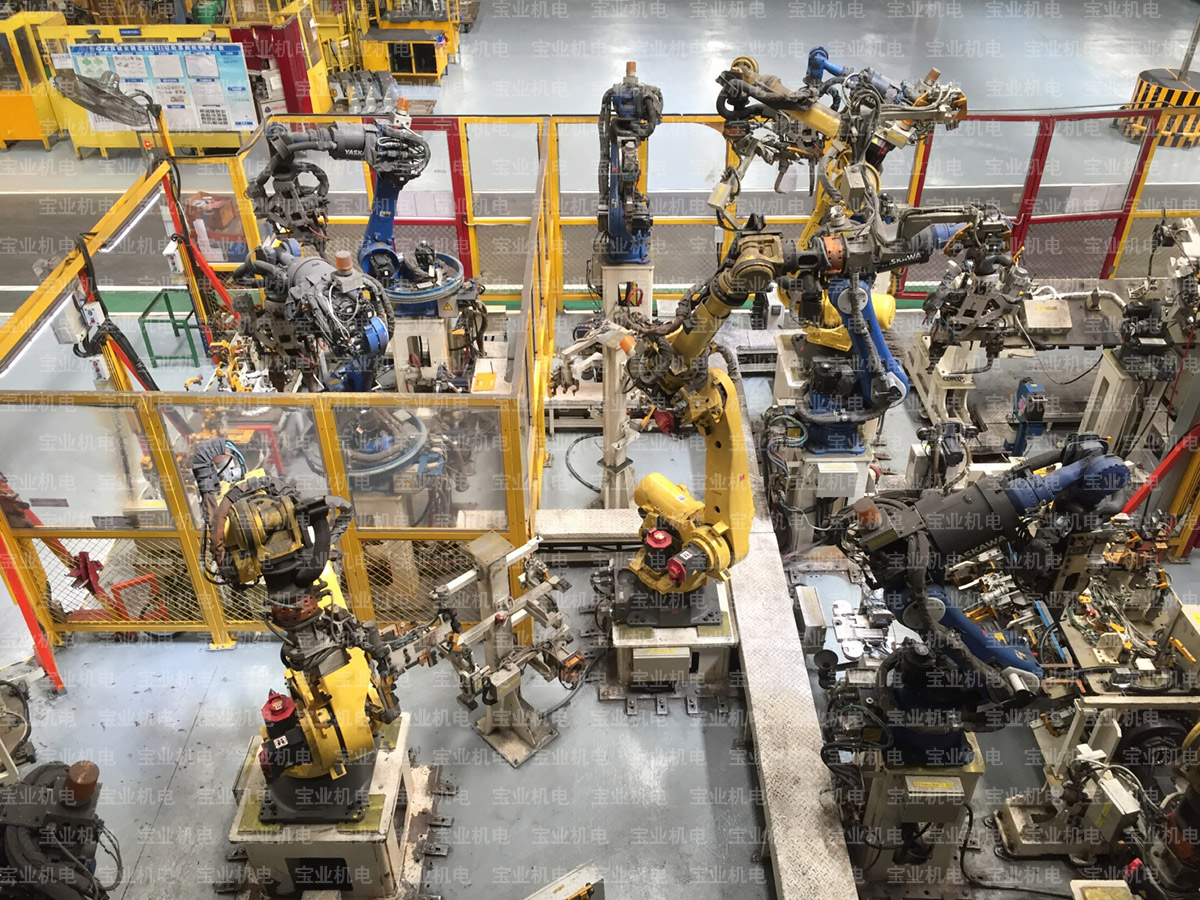

In the production line, a lot of robots are used instead of manual assembly, which reduces the impact of human factors on the quality of the product and can achieve continuous production of 7*24 hours.

Through strict inspection and quality assurance means, the product line has a high rate of up to 99%, which provides an effective guarantee for improving the precision of the assembly of the whole ship and reducing the loss rate of evaporation.

The fixture warehouse can store 3 models and a total of more than 70 sets of fixtures. It can meet the needs of more than 20 robot welding workstations.

In some processes, multiple robots need to cooperate with each other to complete a task together. Shanghai Bao Industry combined with many years of experience in robot applications, the use of multi brand of robots on the production line, and let different brands of robots play their own strengths and work together.

The intelligent fault proofing design is adopted in the production line, which effectively avoids human errors in the feeding section and affects the normal flow line of the production line.

© Copyright SHANGHAI BAOYE M&E TECHNICAL CO.,LTD All rights reserved